Spring Roll Machine and Equipment

Spring Roll Processing Turnkey Project Provider - ANKO

Food and Bread Machine with 30 Years of Spring Roll Equipment Experience

ANKO SR-24 food production for Spring Roll Machinery and Equipment:

Professional Industrial Spring Roll Production Line Supply | ANKO

40 years, 300 recipes, 30 food machines, a team of professional consultants for you to make smart Spring Roll machine ordering decisions. ANKO, since 1978, owns 70% of food machine market in Taiwan and has sold their products to over 112 countries.

From single Spring Roll processing equipment to production line design and manufacturing, ANKO's engineering team has always come up with innovative design to make sure your Spring Roll business is profitable. The Spring Roll equipment you receive from ANKO aims to be cost-effective, and the production capacity is high.

ANKO has been offering customers high-quality industrial Spring Roll processing equipment, both with advanced technology and 40 years of experience, ANKO ensures each customer's demands are met.

Spring roll Production Line | ANKO

Spring roll Production Line | ANKO

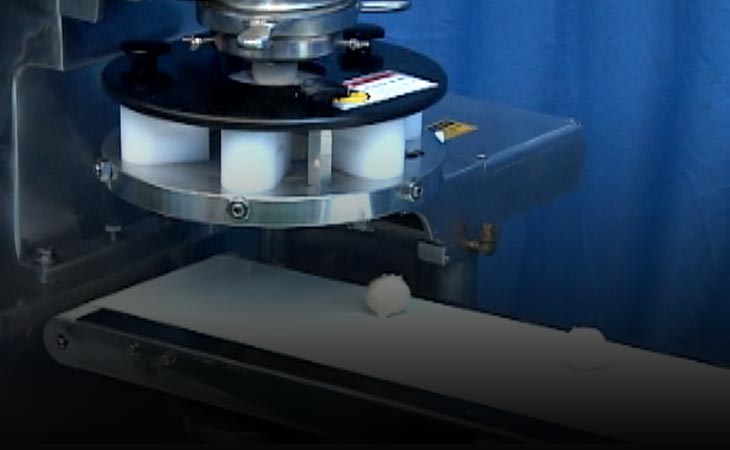

Spring Roll Machine and Equipment (SR-24)

| Location | Taiwan |

|---|---|

| Brand Name | ANKO |

| Model Number | SR-24 |

SR-24 is equipped with special folding & rolling device, to produce spring roll like handmade.SR-24 provides high production capacity and adapts to your needs.

Advantage

New special depositing device can apply with different fillings as below:

- Pure vegetable filling—after cutting, processing and cooking, the max size of leaf vegetable can be up to20X20mm , while root vegetable can be up to 5-8mm cube.? Simply pour the vegetable into the depositor, there’s no need for extra dehydration process, our special depositor has a unique filter device which can extract excessive liquid in filling.? The vegetable fiber texture bite will be majorly kept through our new depositing design.

- Filling of mixed vegetable and meat—the max size of diced meat can be up to 10mm cube, while the max meat to vegetable ratio is1(meat): 2(vegetable).

- Pure meat filling—diced meat can be up to 10mm cube, the popular stir fried loose beef filling in Gulf countries can be deposited and wrapped hassle free.

- Filling of mixing bean sprout, meat and vegetable,while the max ratio is 2(bean sprout): 1(beef). This type of filling is especially popular in Holland.

Specification

| Length | 7500mm |

|---|---|

| Width | 1300mm |

| Height | 2200mm |

| Electricity | 220/380/415/440V,50/60Hz 3Phase, 38kw |

| Capacity | 2400pcs/hr |

| Size of Spring roll | Length: 95-100mm Diameter: 25~30mm, weight of spring roll: 40~50g |

| Pneumatic Air Consumption | 400L/min(@6kg/cm3) |

| Net Weight | 1550kgs |

More Food and Bread This Spring Roll Machine Provided:

Dimsum

Spring Roll

Article Sections

ANKO 20 million USD Investment on a Food Machine Plant

How ANKO Provides Beef Roll Making Machine And Also Delivers Professional Solutions to Win Client's HeartNEW

Chocolate Bakery Equipment Designs For The Most Popular Bread in Japan, "Chocolate Angel Ring"

ANKO Pita Bread Machine Solutions For Golden Top Bakery From Australia

Calzone Bread Machine For A Leading Mexican Food Importer In Japan

ANKO Puff Pastry Machine Supply

Productive & Profitable Puff Pastry Turnkey Project

Crepe Processing Machine For Your New Crepe Idea

Food and Bread Processing Turnkey Project Provider - ANKO

Food Machine. Bakery Machine. Bakery Equipment Product List!

Contact a Food and Bread Processing Turnkey Project Master - ANKO

ANKO FOOD MACHINE CO., LTD. Privacy Policy

Wraps & rolls machine

Machine category

for related products