Productive & Profitable Bakery Bread Machine Turnkey Project

A 100- Layer of Bakery Bread Machine

Taiwan Bakery Bread Machine, Bread Production Equipment Master - ANKO

ANKO's Bakery Bread Machine Turnkey Project For Abou Laban From Syria

ANKO's Bakery Bread Machine Turnkey Project For Abou Laban From Syria

Abou Laban is a food company from Syria and their bakery bread machine turnkey project requires a bakery bread machine manufacturer who has the ability to integrate and design based on their requirements. After consulting with Abou Laban and realizing their requirements regarding bakery bread machine and machine size, production and functionality expectations, ANKO's engineering team designed a professional 64-layer puff pastry production line with bakery bread machine based on the handmade process with an accurate recipe. It is a 10 x 13 meter bread production equipment production line that includes a dough hopper, a butter extruding machine, a sheeting and pressing machine, a folding machine, a flattening and a pressing machine, a swing and folding machine to make layers, a rolling and forming machine, a machine to cut the plastic film and a clamping and stocking machine, etc.

ANKO has sold their bakery bread machine for more than 40 Years to 110 countries, which has allowed them become very competitive in the bakery bread equipment industry. ANKO is able to design bread production equipment with production lines that fabricate more than 100 layers of pastries; in addition, they are the only Taiwan bakery bread machine manufacturer who has the capacity for designing complicated production lines to fulfill each turnkey project's goals for their bakery bread machine buyers.

Bakery Bread, Puff Pastry Production Line, LP-3000M B akery Bread Machine

A). Bakery Bread Machine Rolling Dough Sheet.

A). Bakery Bread Machine Rolling Dough Sheet. B). Place dough into the hopper. Special designed reverses rollers to sheet dough into a thin dough belt. The bakery bread machine does not need a dough sheeter, so it saves time, space and does not destroy the texture of dough.

B). Place dough into the hopper. Special designed reverses rollers to sheet dough into a thin dough belt. The bakery bread machine does not need a dough sheeter, so it saves time, space and does not destroy the texture of dough. C). The margarine is extruded onto the dough belt. Through a special designed wrapping mechanism to wrap the margarine inside the dough sheet. The margarine will not leak out to destory the layers of pastry.

C). The margarine is extruded onto the dough belt. Through a special designed wrapping mechanism to wrap the margarine inside the dough sheet. The margarine will not leak out to destory the layers of pastry. D). Expanding folding mechanism swings the dough belt with margarine inside onto the delivering conveyer to increase the layers of pastry.

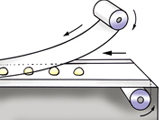

D). Expanding folding mechanism swings the dough belt with margarine inside onto the delivering conveyer to increase the layers of pastry. E). Rolling mechanism rolls up the dough belt into a dough bar by means of the speed difference between the special reollers and conveyor. The bakery bread machine can equip an extra stuffing extruder to roll up a stuffed dough cylinder.

E). Rolling mechanism rolls up the dough belt into a dough bar by means of the speed difference between the special reollers and conveyor. The bakery bread machine can equip an extra stuffing extruder to roll up a stuffed dough cylinder. F). The plain or stuffed dough bar goes through the wrapping mechanism to be formed into dough balls. The both ends are closed to keep from the leak of stuffing and keep the layers.

F). The plain or stuffed dough bar goes through the wrapping mechanism to be formed into dough balls. The both ends are closed to keep from the leak of stuffing and keep the layers. G). The press mechanism presses the finished products onto the conveyor. The bakery bread also can be stacked at a setting quantity, then delivered out by conveyer.

G). The press mechanism presses the finished products onto the conveyor. The bakery bread also can be stacked at a setting quantity, then delivered out by conveyer. H). After resting, place the dough balls between the top and bottom films, then through a sensor, they will be delivered to the pressing location to be pressed into finished products.

H). After resting, place the dough balls between the top and bottom films, then through a sensor, they will be delivered to the pressing location to be pressed into finished products.

Article Sections

ANKO 20 million USD Investment on a Food Machine Plant

How ANKO Provides Beef Roll Making Machine And Also Delivers Professional Solutions to Win Client's HeartNEW

Chocolate Bakery Equipment Designs For The Most Popular Bread in Japan, "Chocolate Angel Ring"

ANKO Pita Bread Machine Solutions For Golden Top Bakery From Australia

Calzone Bread Machine For A Leading Mexican Food Importer In Japan

ANKO Puff Pastry Machine Supply

Productive & Profitable Puff Pastry Turnkey Project

Crepe Processing Machine For Your New Crepe Idea

Food and Bread Processing Turnkey Project Provider - ANKO

Food Machine. Bakery Machine. Bakery Equipment Product List!

Contact a Food and Bread Processing Turnkey Project Master - ANKO

ANKO FOOD MACHINE CO., LTD. Privacy Policy

Wraps & rolls machine

Machine category

for related products

Professional Puff Pastry | Industrial Food Production Line Supply | ANKO

40 years, 300 recipes, 30 food machines, a team of professional consultants for you to make smart food machine ordering decisions. ANKO, since 1978, owns 70% of food machine market in Taiwan and has sold their products to over 112 countries.

From single food processing equipment to production line design and manufacturing, ANKO's engineering team has always come up with innovative design to make sure your food business is profitable. The bakery equipment you receive from ANKO aims to be cost-effective, and the production capacity is high.

ANKO has been offering customers high-quality industrial food processing equipment, both with advanced technology and 40 years of experience, ANKO ensures each customer's demands are met.